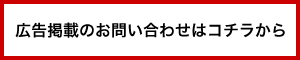

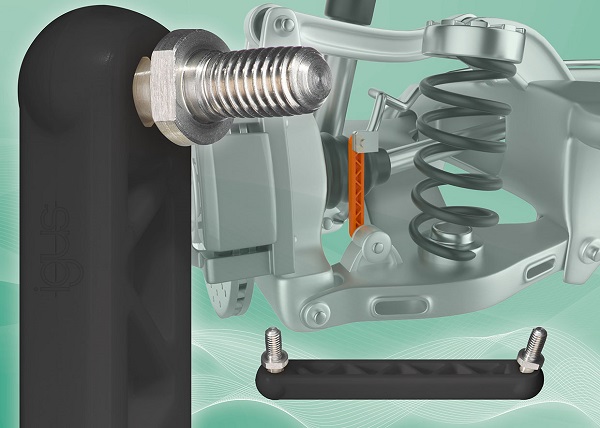

igus developed new elastic double jointigus developed igubal GPZM coupling joint. Its flexible housing material ensures that the ball stud is firmly enclosed and prevents dirt from penetrating into the bearing

Coupling joints are exposed to various types of loads, such as permanent vibrations, edge loads and high tensile forces and compressive strength. The demands on the material used are therefore extremely high. With the igubal GPZM coupling joint, the motion plastics specialist is now presenting a double joint that is not only lubrication-free and maintenance-free, but also 20 per cent more flexible than the conventional solution thanks to a new housing material. This firmly encloses the ball stud, prevents the penetration of dirt and increases the dependability of the moving application.

Spherical bearings made of tribologically optimised polymers are already used in many industries today, the agricultural industry as well as machine and plant construction amongst them,. In the automotive industry alone, the variety of application areas is extremely large: from sensor connections, actuators, valve flaps, shift levers to turbochargers – almost any application of metallic coupling joints can also be implemented with the tribo-polymer version. Light weight, use at temperatures up to 300 degrees Celsius, corrosion resistance and long service life speak for themselves, as do the 40 per cent lower costs when using igubal coupling joints. They are maintenance-free due to the incorporated dry lubrication, no external lubricants are necessary. This also applies to the new GPZM double joint, which igus is currently presenting as part of its autumn innovations.

The double joint is extremely flexible and at the same time resilient. Tests in the 3,800 square metre igus laboratory showed a 25 per cent higher elasticity of the RN283 material compared to the standard material igumid G. The housing material ensures that the ball stud is tightly enclosed in the movement so that it is sealed against the ingress of dust and dirt. Liquefied dust was injected in the test; this contamination has no negative influence on the function due to the elastic material. The abrasion resistance of the metal ball studs was also tested in our own laboratory. The result convinced the igus designers: with a coefficient of wear that is 20 times better than polyamide, the new TPU material prevailed over polyamide and ensures significantly increased dependability in movement.