NTN has developed the “DLC Coating Spherical Roller Bearing” for wind turbine main shaft with significantly improved wear-resistance by applying the DLC (diamond like carbon) coating to the surface of rollers.

For wind turbine main shaft bearings (hereafter, main shaft bearings), spherical roller bearings, which has high-load capacity and excellent allowable capability for installation misalignment, are widely used. The main shaft bearing repeats starting and stopping according to wind conditions and it is used at extremely low speeds. The main shaft bearings used in such environment has a problem of the wear on the raceway surface and it will develop to flaking and cracking due to rolling sliding specific to spherical roller bearing and metal to metal contacts on the raceway surface caused by insufficient lubrication.

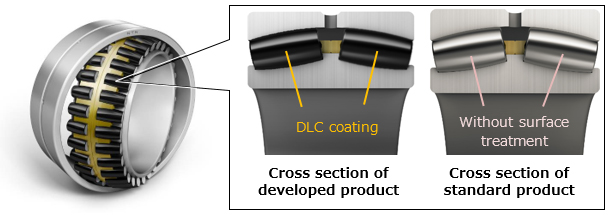

NTN improved significantly wear-resistance of this developed product on raceway surface by applying a DLC (Diamond-Like Carbon) coating that has high adhesion and is difficult to remove on the rolling surface of roller.

DLC coating is hard film with amorphous structure in which carbons having a diamond structure and a graphite structure are irregularly mixed.

The newly developed DLC coating has a three layer structure, (1) a metal under layer to increase adhesion to the base material, (2) an intermediate layer to avoid a sudden change in hardness between the under layer and the top layer, and (3) a very hard surface layer.

Even under severe lubrication conditions, the DLC coating with high adhesion continuously provide high performance. Almost no wear occurs with this developed product under accelerated testing conditions in which the raceway surface of a standard product without a DLC coating make flaking from wear in one month.

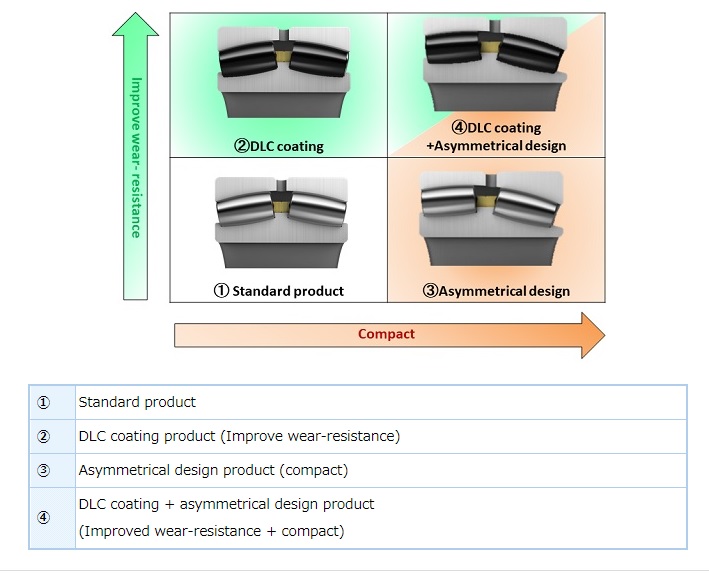

NTN has already begun mass production of this developed product, and will further propose this product as well as strengthening sales of this product as an aftermarket product that responds to premature damages caused by wear on the raceway surface in particular. The new coating technology can also be combined with asymmetrical designed product, which was developed in 2017 to make wind turbine more compact.

NTN is working on expanding sales in wind turbines market by expanding the product lineup so that customers can select the most suitable option from DLC coating and asymmetrical design of this developed product to meet the needs.

Features

1.Significantly improved wear-resistance of raceway surface

2.DLC coating which has a high adhesion with a three layer structure:Three layer structure of the under layer, the intermediate layer, and the surface layer provides high adhesion to the film.No flaking on DLC coating under the condition of boundary-lubrication, actual maximum contact stress of the actual DLC coating, and rolling sliding.

Application

Industrial machinery used under severe lubrication conditions where it is difficult to form oil film, such as wind turbine